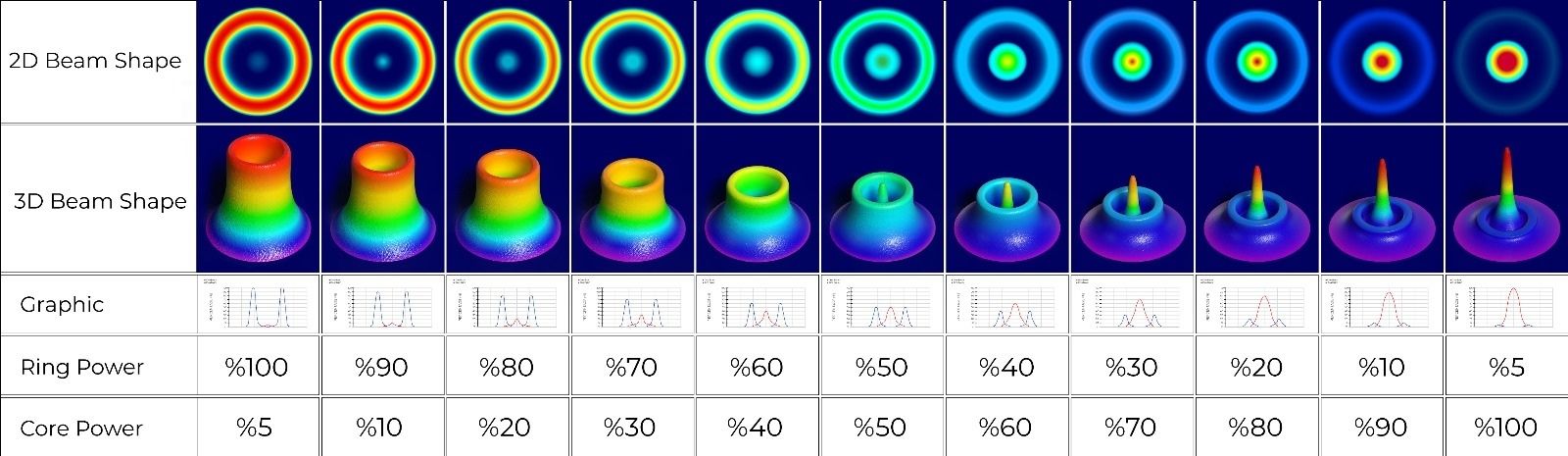

Adjustable Beam Lasers

Laser systems equipped with "ABL" technology, also known as "Tunable Beam Lasers", are high-tech devices widely used in industrial applications. These systems are specifically designed to provide superior performance in processes requiring high precision, such as metal welding.

These lasers typically use an array of mirrors or lenses to focus a laser source. However, tunable beam lasers are equipped with advanced optical systems and control algorithms. In this way, the laser beam can be directed to the targeted material much more dynamically.

Especially "ABL" technology offers the ability to adjust the intensity, focal length and even wavelength of the laser beam. This provides greater control and flexibility in where the laser focuses. These systems are also equipped with the ability to focus the laser beam at several different points.

Superior control capabilities make it possible to precisely direct the laser beam at every stage of the welding process. This allows for more precise and repeatable results when joining metals. Deep penetration capabilities refer to the ability of the laser beam to penetrate into the material. This paves the way for creating more robust and flawless sources.

Advanced tunable beam lasers offer this dynamic control, as well as the ability to dynamically shape multiple lights. This feature stands out as an important element in creating perfect welds in complex geometries and different materials.

As a result, adjustable beam lasers are a technology that makes it easier to weld metals together with superior control and deep penetration capabilities thanks to "ABL" technology. . Its dynamic shaping properties and multi-beam directing ability pave the way for creating perfect welds and finds wide use in industrial applications.

ROBOTIC REVOLUTION IN LASER WELDING

-

Technical Advantages of 6-Axis Robots

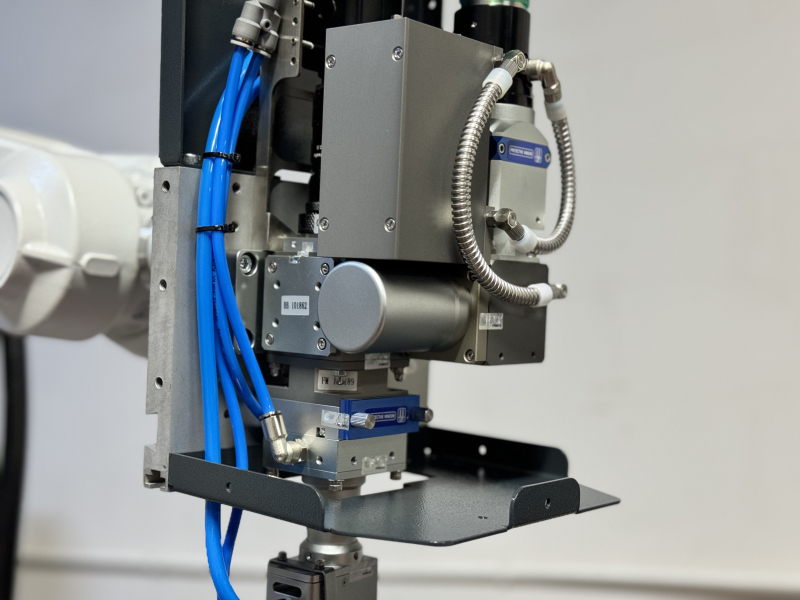

6-axis robots enable the production of complex geometries thanks to their freedom of movement. Compared to other types of robots, these robots can access workpieces from different angles and positions, making them ideal for precision operations such as laser welding. Additionally, these robots can operate at high speed and consistency, thus increasing the efficiency of production processes. -

The Role of 6-Axis Robots in Laser Welding

Laser welding is a method of joining materials using a high-energy beam. This process is especially advantageous in applications requiring high precision. 6-axis robots, on the other hand, precisely guide the laser welding head over the workpiece, providing superior welding quality even in hard-to-reach points. This combination has revolutionized the production of complex parts in various industries such as automotive, aerospace and medical devices.

The use of 6-axis robots in laser welding has revolutionized the manufacturing industry. This combination of technologies has significantly increased the speed, efficiency and quality of production processes. With developing technologies, it is clear that this trend will continue in the future and will continue to change the face of the manufacturing industry.

-

Optical Systems and Laser Focusing

Laser welding heads combine the complexity and precision of optical systems. These systems create the desired effect in the welding area by correctly directing and focusing the laser beam. In applications requiring high precision, accurate focusing of the laser is critical, which highlights the importance of laser welding heads. -

Gas Shielded Atmosphere and Nozzles

During the laser welding process, it is necessary to protect the welding area with a correct gas atmosphere. This is important to improve weld quality and minimize material deformation. Laser welding heads are equipped with special nozzles that allow precise application of this gas. While nozzles control the gas flow, they also ensure the removal of smoke and residues that may occur during the process. -

Sensor Technology and Feedback Systems

Modern laser welding heads are equipped with various sensors to collect data in real time during the process. These sensors constantly monitor temperature, material flow and other important parameters in the weld zone. The obtained data is transmitted to the control unit through feedback systems and enables automatic corrections to be made during the process. -

Integration and Harmony

Laser welding heads are often integrated with automation systems such as industrial robots or CNC machines. This integration enables laser welding processes to be automated and more complex part geometries to be machined. They are also designed to be compatible with different laser welding systems, so they can meet various application requirements.

Laser welding heads form the basis for uninterrupted and high-quality welding processes in industrial production. Thanks to constantly evolving technologies and design principles, laser welding heads continue to offer revolutionary solutions for faster, more precise and more reliable welding processes.

-

Thermal Management and Temperature Control

Laser power supply cooling systems maintain the optimum temperature range required for proper operation of the electronic and optical components inside the laser device. These systems prevent the laser from overheating, preventing performance loss and system malfunctions. At the same time, it ensures long-term and high-efficiency operation of the laser. -

Refrigeration Technology

Laser power supply cooling systems generally work with refrigeration technology. These systems absorb the heat inside the laser device and throw it out. High performance compressors and refrigerants are used to ensure stable operation of the laser. Additionally, these systems are often based on the liquid cooling principle, resulting in higher efficiency and less energy consumption. -

Precise Control and Automatic Settings

Modern laser power supply cooling systems are equipped with precise temperature control and automatic settings. These systems automatically adjust the cooling capacity depending on the operating conditions of the laser and ensure optimum performance. Additionally, thanks to remote access and monitoring features, it is possible to monitor the system status remotely and intervene when necessary.

-

Two Separate Beam Controls

Dual beam output laser power supplies produce two different laser beams that can generally be controlled independently of each other. This allows different operations to be performed simultaneously or sequentially. Each beam can be individually adjusted in terms of power, speed, focus and other parameters, allowing multiple processes to be easily managed within the same system. -

Flexibility and Application Diversity

Dual beam output laser power supplies adapt to a wide range of applications. For example, one beam can be used for precision micro-welding operations, while the other beam can be used to machine larger areas. It is also ideal for processing different materials and thicknesses, providing flexibility in industrial production processes. -

Energy Efficiency and Performance

Dual beam output laser power supplies are optimized for energy efficiency and performance. Control of each beam optimizes energy consumption, reducing operating costs while achieving high-quality and consistent results. These systems are designed to provide high efficiency and stability in industrial production. -

Integration and Automation Capabilities

Dual beam output laser power supplies can often be integrated with automation systems such as industrial robots or CNC machines. This allows processes to be automated and makes production processes more efficient. Additionally, thanks to remote access and monitoring capabilities, it is possible to monitor the system status and intervene when necessary.

Dual beam output laser power supplies are an innovative solution that increases flexibility, control and performance in the laser welding industry. Thanks to constantly evolving technologies and design principles, these systems are continually optimized to meet the highest standards in industrial applications.